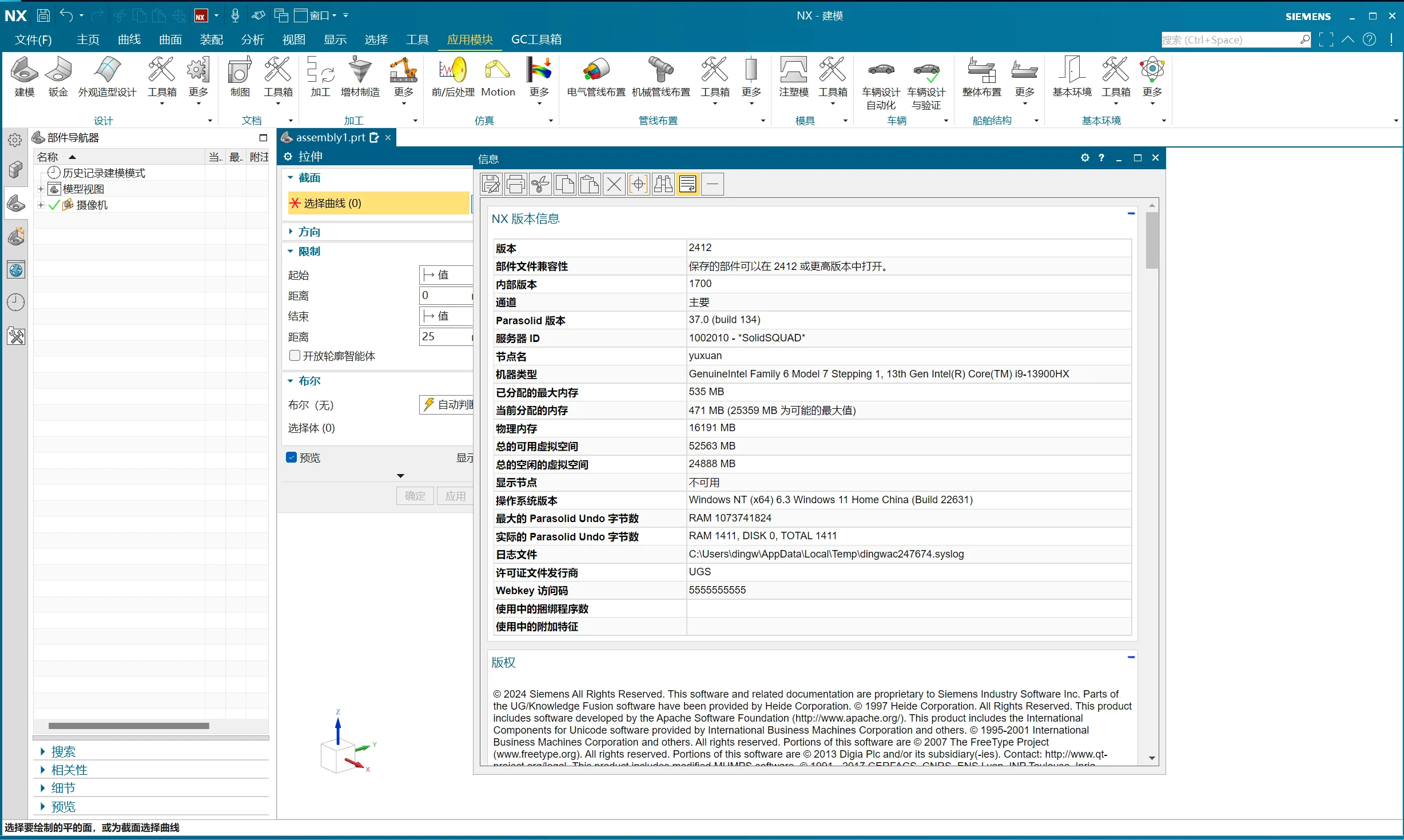

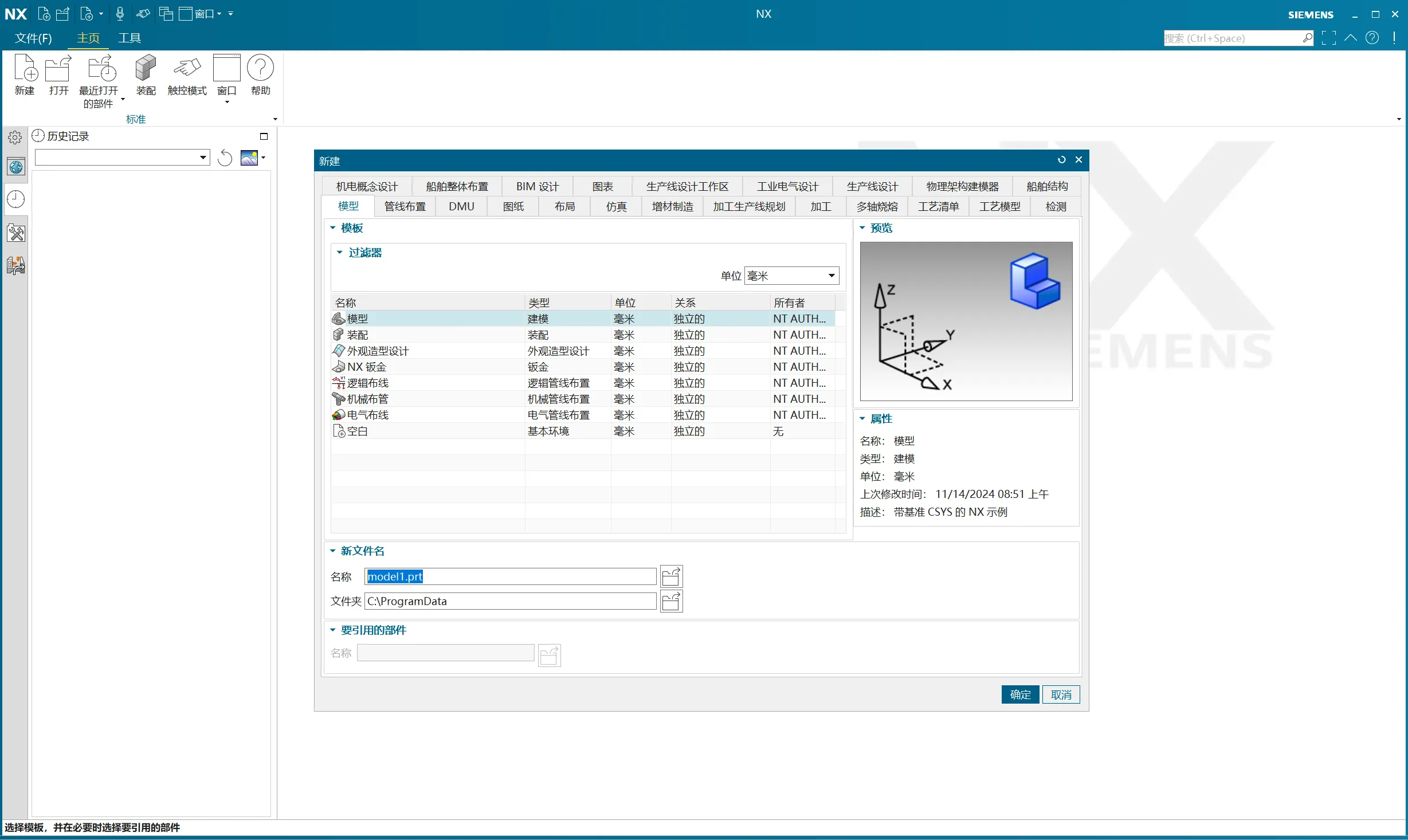

NX 2412 Build 1700NX is a leading CAD/CAM/CAE system newly launched by Siemens. This software is widely used in industries such as product design, mold design, and machining. It not only provides conventional CAD functions such as 2D drawing and 3D modeling, but also offers more advanced features such as reverse engineering, freeform surface design, and motion simulation. The NX 2412 Series adds AI capabilities. With AI becoming ubiquitous today, this NX update also adds AI-driven design features to help users improve and accelerate their design processes. New AI-driven tools such as topology optimization, performance prediction, and gyroid modeling combine with existing features such as command prediction and selection prediction to significantly improve efficiency.

Siemens NX adds multiple design capabilities

Siemens NX launches enhancements to provide users with more AI and generative design capabilities

Customers can now use NX X and Zel X cloud software to facilitate cross-domain and cross-departmental collaboration

Siemens Digital Industries Software announced several new capabilities for its product engineering software, NX™. Part of the Siemens Xcelerator portfolio, the enhancements to NX are designed to help designers and manufacturers across a wide range of industries deliver better, more optimized products to market faster.

Release NX X

Building on the foundation of NX products, NX™ X software allows users to access it from the cloud and introduces an embedded data management module based on Siemens' product lifecycle management software, Teamcenter®. Leveraging information securely stored in Siemens' cloud-based Software as a Service (SaaS) infrastructure, it helps users unlock a higher level of NX applications, thereby achieving greater flexibility, scalability, and collaboration.

After using NX X software, David Doral, CEO of the startup Dovetail Electric Aviation, said: "As a startup striving to push the boundaries of innovation, we urgently need industrial software that can help us explore various options and ensure product performance. Siemens' NX X provides us with future-proof, next-generation product engineering capabilities. Its licensing model allows us to use the more scalable and flexible Siemens Xcelerator solution portfolio to achieve our company goals."

NX X is an enhanced cloud-based product engineering software that supports desktop installation and browser streaming via AWS Cloud services. NX X also offers secure data management capabilities for seamless collaboration and enhanced PLM functionality with Teamcenter® X software, providing users with greater flexibility and enhanced local collaboration while reducing IT management time. NX X offers a flexible and scalable licensing model, enabling customers to access NX add-ons and advanced features in a more adaptable and cost-effective manner. With over 100 available products and extensions, companies can identify add-ons that best suit their workflows and customize them to meet their project needs. NX X can also be combined with Siemens' newly released Zel X™ software. Built on the same architecture as NX, Zel X is a next-generation, browser-based engineering application that integrates with NX and other Siemens Xcelerator software solutions to help streamline manufacturing and shop floor operations.

Creating an immersive future design space for engineers and designers

NX™ Immersive Explorer software will provide users with a gaming-like immersive experience, allowing them to conduct design reviews, virtual commissioning, and sign-off in a highly realistic environment, whether on the desktop or in virtual reality. NX Immersive Explorer will be available in December 2024 and will support major HMD hardware options, allowing users to immerse themselves in a hyper-realistic interactive environment and gain valuable insights earlier in the design process, thereby reducing the cost of creating physical prototypes. NX Immersive Explorer helps users focus more closely on specific parts of an assembly, inspect individual components, and document design review results by adding markups and annotations, allowing users to approach the entire design process from a new perspective.

New AI features

AI is ubiquitous today, and this NX update adds AI-powered design capabilities to help users improve and accelerate their design processes. New AI-powered tools like Topology Optimization, Performance Predictor, and Gyroid Modeling combine with existing capabilities like Command Prediction and Selection Prediction to significantly increase efficiency.

Performance Predictor is an AI-powered design simulation tool that verifies material selection and mechanical properties of individual parts, enabling design teams to validate and test design iterations in real time, accelerating innovation and reducing costly errors.

When combined with AI-driven topology optimization and new Gyroid and infill design capabilities, as well as Design Space Explorer, coming in 2023, these capabilities will help design teams create better parts that not only meet performance requirements but also allow them to conduct lightweighting studies and leverage the advantages of additive manufacturing as needed.

Accelerate part manufacturing with greater controllability

At the same time, this update also improves the user control level and workflow productivity of NX CAM and NX Additive Manufacturing (AM), allowing users to have greater confidence in their part designs and obtain high-quality components faster. Now, the high-speed machining strategy Enhanced 3D Adaptive Roughing can help programmers automatically specify the start position, thereby improving machining efficiency and extending tool life. Similarly, drilling operations have also been improved to more accurately control tool movement, ensure machining security, and improve surface quality. Not only that, Siemens has also updated the Cloud Connect Tool Manager to help simplify CNC programming, while allowing users to directly access tool supplier product catalogs, which can associate machining settings with cutting tools, thereby speeding up programming.

New features and enhancements in NX also streamline build preparation for additive manufacturing of metal and polymer parts. A new facet selection method simplifies the creation of support structures for parts modeled with faceted geometry. Additionally, new capabilities such as sub-nesting, sinter box creation, patch distribution calculation, and 3D packing optimization significantly simplify and accelerate polymer build preparation. A new build processor streamlines the generation and output of print job files from NX to SLM Solutions and Trumpf metal 3D printers. New multi-axis additive build rules enable the creation and reuse of custom process parameters, contributing to high-quality manufacturing.

Enhancements for the Electronics and Semiconductor Industries

The newly released Managed Environment for Electronics Design helps create a continuous digital thread, linking data from different software across the Siemens Xcelerator platform, including NX, Capital™ for electrical/electronic (E/E) system development, Xpedition™ for PCB design, and Teamcenter for product lifecycle management. This strengthens the integration between these software components and enables seamless data flow and collaboration between electronic and mechanical design teams. This unified data management platform, encompassing both electrical/electronic and mechanical design, streamlines ECAD and MCAD processes.

Building Information Modeling (BIM) capabilities in NX

NX for BIM software offers a complete set of Building Information Modeling (BIM) tools, providing a unified multidisciplinary platform for architecture, engineering, and construction (AEC) workflows. The advantages of this software are particularly significant for fields that typically require multiple different software products to handle the architectural and construction design process. New NX for BIM features include an IFC data converter, stair tools, and the ability to import information from 3D BIM libraries, improving interoperability and workflow efficiency. In addition, the newly launched NX for Concrete Design add-on module plays an important role in modular construction operations and can further improve the fidelity of digital twins of concrete structures.

NX 2412 Build 1700 Features

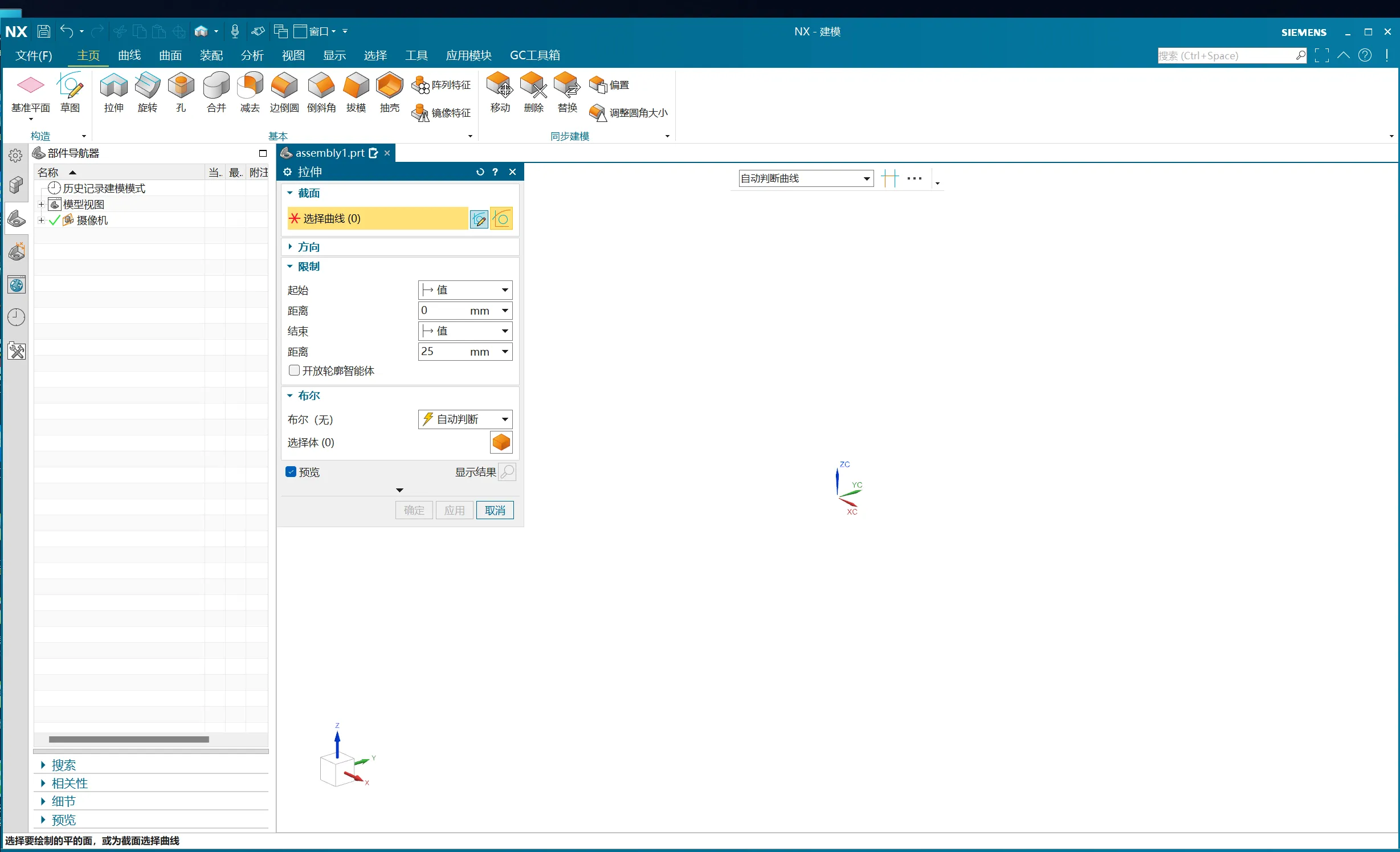

1. Enhanced Sketch function

Efficient sketch creation

In terms of sketching, NX 2412 Build 1700 likely builds on the strengths of previous versions and further improves them. It further reduces the number of steps required to create sketches compared to previous versions. For example, the number of clicks required to initialize a sketch is reduced, eliminating the need to enter planes, vectors, and points. This is achieved through optimization of the software's internal algorithms and improvements to the user interface design.

Features like visual indicators could be improved. When users start sketching on a plane, there are clear visual indicators, which helps users more intuitively understand the status of the sketching, thereby improving the efficiency and accuracy of sketching.

Powerful geometric constraints and relationship processing

The software automatically applies geometric constraints based on surrounding geometry, eliminating the need to manually add constraints one by one during sketching. Furthermore, regardless of the data source, it can be seamlessly processed, meaning that both externally imported and internally created data can be seamlessly processed during the sketching process without compatibility issues.

(2) Improved algorithm modeling capabilities

Efficient implementation of complex designs

New algorithmic modeling applications allow designers and engineers to more easily create complex designs. Complex industries such as automotive, aerospace, energy, and consumer product manufacturing often require creating complex product forms and functions. The algorithmic modeling capabilities in NX 2412 Build 1700 enable these complex designs to be constructed algorithmically, which would otherwise take days of effort or require engineers to have advanced programming knowledge.

Algorithm reusability

The design and engineering community can save created algorithms as templates for reuse in similar design workflows. This significantly improves productivity because once an algorithm is proven effective, it can be directly applied to subsequent similar projects without having to redevelop the algorithm. These algorithms can be easily constructed and edited using the Logic Editor, which provides an intuitive interface that allows engineers and designers to operate even without a deep programming background.

(3) New features of convergent modeling

Integrated Modeling Updates

In convergent modeling, CAE (Computer-Aided Engineering) can be updated using scanning and related technologies, increasing the value of convergently generated geometry downstream without the need for reverse engineering. This is crucial for improving the efficiency and quality of engineering design. For example, during product optimization, improvements can be made directly based on an existing convergent model without rebuilding the entire model.

Mixed Geometric Entity Operations

Aggregate entities can be composed of mesh and analytical surfaces, creating hybrid geometries. These hybrid geometries provide greater flexibility for modeling complex products. For example, when dealing with products with unique structural or surface characteristics, these hybrid geometries can be used to accurately model them. Furthermore, new commands, such as the Replace Mesh Surface command, allow users to easily replace portions of the mesh, which is very useful during model modification and optimization.

Implicit Modeling, a new optional module, enables reliable modeling of complex designs. Industries such as aerospace, energy, medical, and automotive, which are particularly benefiting from the additive manufacturing market, often face challenges dealing with complex geometries and structures. Implicit Modeling can meet these demands by creating equation-driven structures.

4. Additive Manufacturing Design Improvements

Efficient use of resources

Compared to traditional CAD methods, NX 2412 Build 1700 enables the rapid creation of powerful designs for additive manufacturing with fewer resources. This helps companies reduce costs and improve production efficiency. For example, when designing complex parts, tasks can be completed without excessively increasing resources (such as computing resources and materials).

Lattice structure optimization

The Lattice Structure update improves engineering efficiency and quality. Lattice structure creation time has been significantly reduced, for example, by 93%. This allows for faster generation of lattice structures in designs, providing more possibilities for structural optimization. Furthermore, higher-quality engraving results in cleaner results, which helps improve product appearance, quality, and performance.

The WrapMesh function wraps the part of interest into a watertight mesh object, and some options can be used to control the size of the mesh and gaps. This is very useful when dealing with complex geometries or performing specific additive manufacturing processes. For example, when manufacturing parts with special internal structures, the mesh and gap sizes can be accurately controlled to meet process requirements.

(V) Model-Based Definition (MBD) Functional Expansion

Efficient annotation creation

In model-based definition, creating annotations has traditionally been a manual process, but NX 2412 Build 1700 introduces a more efficient approach. For users who already use MBD, this can improve efficiency; for those who haven't yet, this version of the MBD solution can serve as a starter and accelerator, as adding data, for example, takes less time.

PMI automatically creates intelligent

The automated creation of PMI (Product Manufacturing Information) introduces an AI-driven solution. It provides an interactive LogicEditor diagram interface that supports the authoring and execution of PMI rules. This not only accelerates and simplifies tedious manual work but also makes it easy for users without MBD experience to operate. By gaining better insights through richer data, the company can capture design data more deeply and eliminate the need to rely on a variety of experts to ensure requirements are met, resulting in the production of high-quality parts in a shorter time.

(6) Assembly upgrade in multi-user design

Collaborative design optimization

The assembly has been upgraded for multi-user design scenarios. NX 2412 Build 1700 supports a true collaborative design environment by actively notifying users of changes in the design context. When multiple users work in the same area, opening each other's parts (not in terms of file ownership, but in terms of attribution) ensures that everyone is on the same page and aware of the latest design changes. For example, in the product development process of a large interdisciplinary team, people with different disciplines (such as mechanical engineers, electrical engineers, etc.) can design different parts of the product at the same time and be able to be informed of other people's design changes in a timely manner to avoid design conflicts.

Reduce rework

By detecting changes and automatically updating designs, time can be saved and rework eliminated. For example, if one engineer modifies the dimensions of a part, other related parts can automatically update to accommodate the change without requiring other engineers to manually adjust related design content.